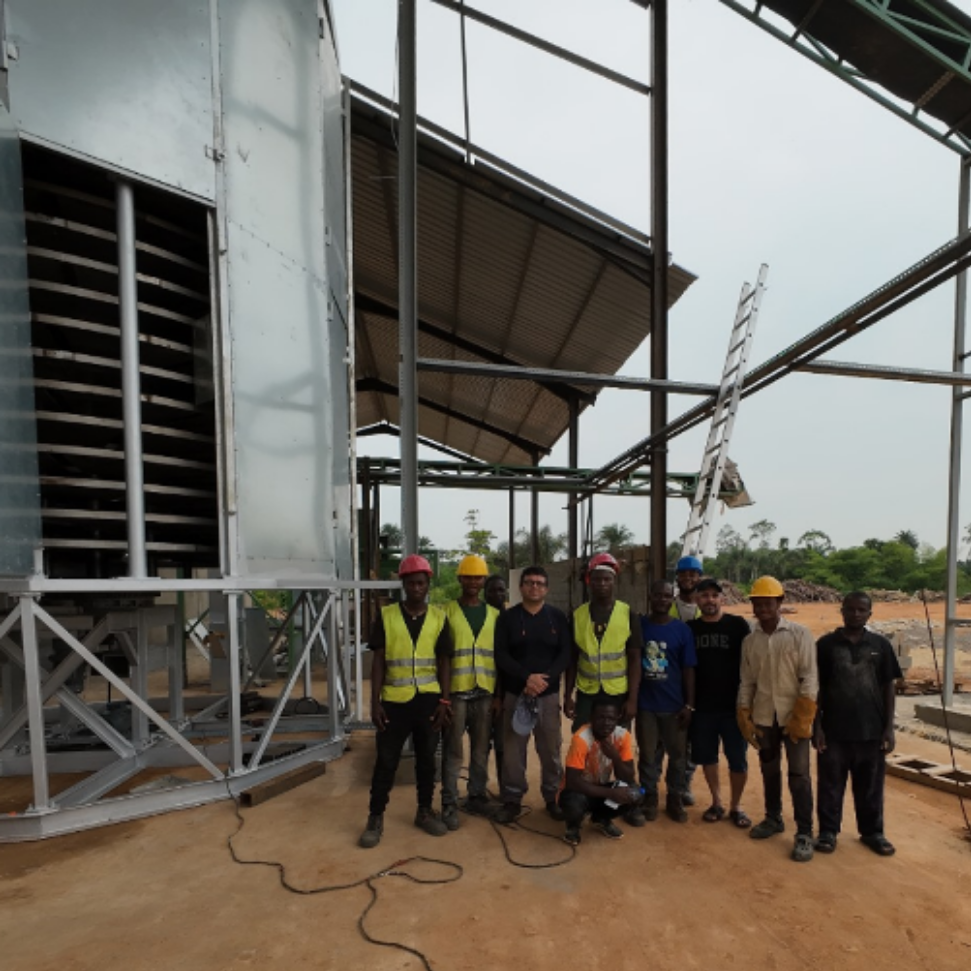

Thermal Processing

Rotary Tray Dryer

Rotary Tray Dryer-MaxiGEN, is a unique and highly efficient drying system designed to process a variety of materials with a wide range of characteristics.

Rotary Tray Dryer Features

- Rotary Tray System: Features vertically stacked, rotating circular trays that allow materials to move progressively through the dryer for controlled drying.

- Continuous Operation: Material is continuously fed from the top, moving through each tray in sequence, ideal for high-capacity applications.

- Uniform Drying: Ensures even drying of materials by maintaining consistent airflow and temperature across each tray, preventing hot spots and ensuring uniform moisture removal.

- Adjustable Drying Parameters: Allows precise control over temperature, airflow, and residence time, optimizing the drying process for various materials and moisture levels.

- Energy Efficiency: Utilizes a direct contact drying method that minimizes heat loss and maximizes heat transfer, reducing energy consumption and operational costs.

- Compact Vertical Design: The vertical configuration saves valuable floor space and accommodates large volumes of material, making it suitable for facilities with limited space.

- Low Maintenance: Designed with minimal moving parts and robust construction, reducing wear and tear and lowering maintenance needs.

- Versatile Material Handling: Capable of drying a wide range of materials, including powders, granules, flakes, and pastes, suitable for industries like chemicals, food, pharmaceuticals, and minerals.

- Gentle Drying Process: The slow rotation of trays and controlled airflow minimizes mechanical stress on materials, ideal for fragile or sensitive products.

- Dust and Vapor Control: Equipped with systems to manage dust and vapor emissions, ensuring a clean and safe operating environment, especially for materials that produce fine particles or volatile compounds.

What Materials Can Be Dried Using the MaxiGEN Dryer?

- Chemicals: Various chemical compounds, intermediates, and catalysts.

- Fertilizers: Organic, Organo-mineral, NPK

- Pharmaceuticals: Active pharmaceutical ingredients (APIs), powders, and granules.

- Food Products: Fruits, vegetables, spices, coffee, grains.

- Minerals and Ores: Clays, limestone, coal, and other mineral products.

- Polymers and Resins: Plastics and resins in granular or powder form.

- Biomass and Organic Materials: Wood chips, sawdust, and other organic materials used for energy production or composting.

The MaxiGEN Dryer is incredibly versatile and can dry a wide range of materials, including but not limited to above.

Working Principle of the MaxiGEN Dryer

- Material Loading: The drying process begins with the material being fed onto the top tray of the dryer through a feed chute. The material can be in various forms, such as powders, granules, flakes, or pastes. The feed rate is carefully controlled to ensure optimal drying conditions.

- Rotary Tray Mechanism: The dryer consists of a series of circular trays that are stacked vertically and mounted on a central rotating shaft. As the trays rotate around the shaft, the material is gradually moved from the center to the edge of each tray by the gentle centrifugal force generated by the rotation.

- Tray Transfer System: At the edge of each rotating tray, there are strategically placed slots or discharge points that allow the material to fall onto the tray directly below it. This process is repeated through multiple stages as the material moves downward through the dryer, allowing for gradual and consistent drying.

- Hot Air Circulation: A controlled stream of hot air is introduced into the dryer, typically from the bottom, and it flows upwards through each tray. This air flow can be either cross-flow (horizontal) or counter-flow (vertical) depending on the design and the drying requirements of the material. The hot air passes through the material bed on each tray, providing direct contact with the material, which promotes efficient heat and mass transfer.

- Moisture Removal: As the hot air flows through the trays, it absorbs moisture from the material. The consistent exposure to controlled heat and airflow ensures uniform drying across all trays, preventing any material from being over-dried or under-dried.

- Temperature and Airflow Control: The dryer is equipped with adjustable controls for temperature and airflow, allowing precise tuning of drying conditions to suit the specific characteristics of the material being dried. This control ensures that sensitive materials are not damaged while achieving the desired level of dryness.

- Discharge of Dried Material: Once the material has reached the desired moisture content, it is discharged from the bottom tray. The dried material is then collected for further processing or packaging.

The MaxiGEN Dryer, also known as the Rotary Tray Dryer, operates on a unique principle of continuous, direct contact drying. It is designed to efficiently remove moisture from various materials through a combination of controlled heat and airflow.

Products

- Compost

- Biochar

- Granular NPK Fertilizer

- Digestate

- Calcium Carbonate

- Bauxite

- Boric Acid

- Calcium Chloride

- Copper Powder

- Chocolate

- Cocoa

- Kaolin

- Lithium Carbonate

- Malic Acid

- Seeds

- Soda Ash

- Sludge

- Sodium Bicarbonate

- Vegetables

- Vitamin C

- Zinc Oxide

- Zinc Powder

Mineral Dryer

Continuos Vertical Industrial Dryer

Digestate Drying for Biogas Plants

Turbo Tray Dryer

| Modal | MaxiGEN-3038 | MaxiGEN-3048 | MaxiGEN-3058 | MaxiGEN-5058 | MaxiGEN-5068 | MaxiGEN-5078 |

|---|---|---|---|---|---|---|

| Diameter (mm) | 3000 | 3000 | 3000 | 5.000 | 5.000 | 5.000 |

| Height (mm) | 3800 | 4800 | 5800 | 5800 | 6800 | 7800 |

| Working Principle | Multi-Tray Rotary Dryer | Multi-Tray Rotary Dryer | Multi-Tray Rotary Dryer | Multi-Tray Rotary Dryer | Multi-Tray Rotary Dryer | Multi-Tray Rotary Dryer |

| Feeding System | Screw Feeder | Screw Feeder | Screw Feeder | Screw Feeder | Screw Feeder | Screw Feeder |

| Discharging System | Automatic Pneumatic | Automatic Pneumatic | Automatic Pneumatic | Automatic Pneumatic | Automatic Pneumatic | Automatic Pneumatic |

| Total Motor Power | 20 kW | 20 kW | 20 kW | 50 kW | 50 kW | 50 kW |

| Heating Sources | Natural Gas / LNG / Steam / Electric | Natural Gas / LNG / Steam / Electric | Natural Gas / LNG / Steam / Electric | Natural Gas / LNG / Steam / Electric | Natural Gas / LNG / Steam / Electric | Natural Gas / LNG / Steam / Electric |

| Operation | Fully Automated | Fully Automated | Fully Automated | Fully Automated | Fully Automated | Fully Automated |