Thermal Processing

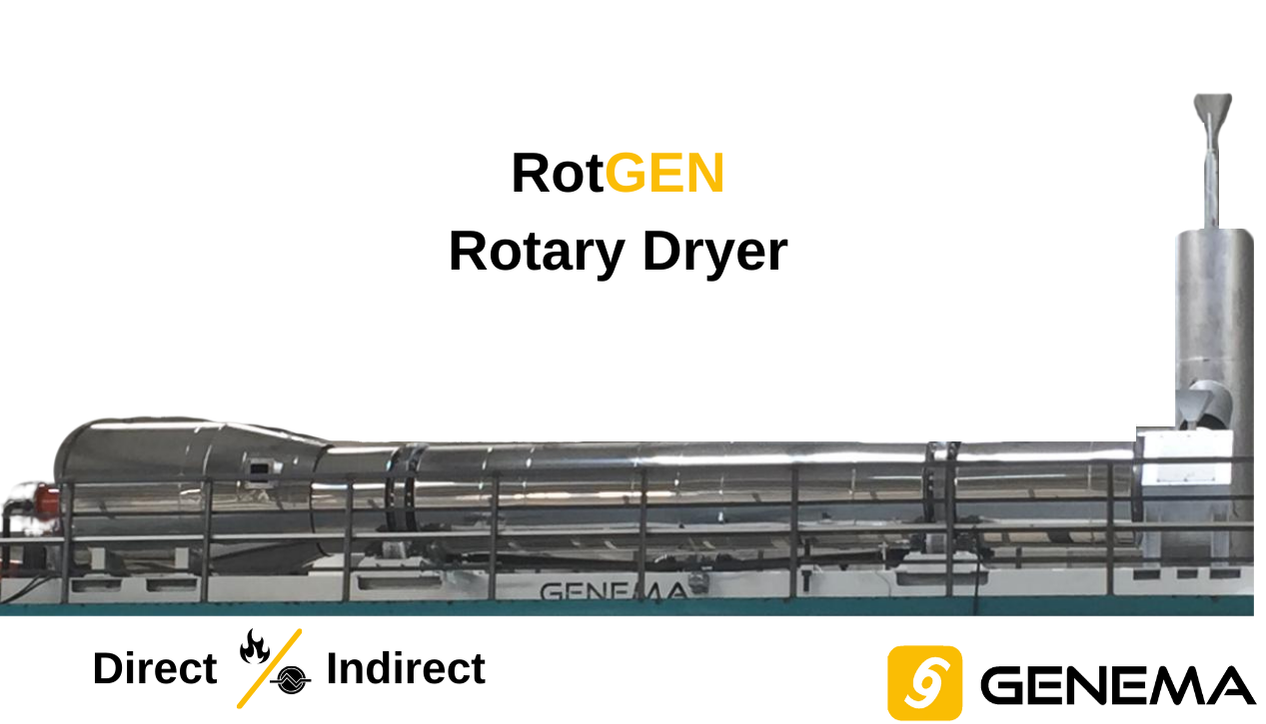

Rotary Dryer

Rotary dryer is a drying machine widely used in various industries. This machine is designed to reduce or minimize the moisture content of various materials. Rotary dryers dry materials with the help of hot air in a large rotating drum.

Rotary Dryer Features

- Rotary drum dryer is suitable for high capacity operation.

- Rotary drum dryers can dry materials in different forms such as granules, powders, sludges and chips.

- Rotary drums maximize contact between hot air and material.

- Application-specific design can be made by considering drum length, drum diameter, rotation speed, air flow direction.

- Product standardization can be achieved by equipping rotary dryers with advanced process controls.

Areas of Use of Rotary Dryers

Rotary dryers are widely used in many sectors, including but not limited to the following industries:

- Mining and Mineral: Sand, coal, metal ores, bauxite, copper, nickel, NPK and other mineral materials

- Chemical Industry: Chemical powders, pellets, granules, pharmaceutical

- Agriculture Sector: Agricultural products, grains, seeds and other agricultural by-products

- Biomass: Wood chips, sawdust, organic waste

- Construction Industry: Sand, gravel, limestone

- Food Industry: Food additives

Working Principle of Rotary Dryers:

- Material Feed: Wet material is fed from one end of the rotary drum. The material moves in the rotating drum throughout the drying process.

- Rotating Drum: The drum, the main part of the rotary dryer, rotates around its axis. This rotational movement ensures that the material is homogeneously mixed in the drum and comes into contact with the drying air.

- Heat Source and Hot Air Flow: A heat source is used to dry the material inside the drum. This heat source is hot air, usually generated by a burner. The hot air is introduced into the drum and evaporates the moisture from the material, thereby drying it.

- Moisture Evaporation: As the material rotates in the drum and comes into contact with the hot air, the moisture in it evaporates. This evaporation process occurs through convection; the hot air transfers heat from the material and allows the moisture to evaporate.

- Discharging the Dried Material: After the drying process is complete, the dried material is removed from the other end of the drum. The discharged material is usually collected via a conveyor.

- Air Exhaust and Dust Collection: After the hot and humid air leaves the drum, it is usually directed to a dust collection system. This system separates the dust particles from the air so that clean air is exhausted.

Rotary drum dryer for biomass drying

Rotary dryer for wood chips-sawdust-agricultural waste-coal drying

Rotary dryer for sludge/mineral drying