Thermal Processing

Rotary Calciner

Flash Dryer

Spray Dryer

Would you like us to dry your material?

Industrial Drying Services

Chemical

Mineral

Agriculture

Fertilizer

Pharmaceutical

Food

Biomass

Institutions

Parameters

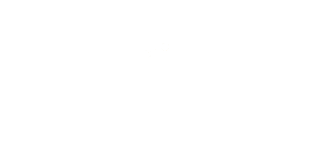

Typical Flowchart

Drying Method

Material Form

Moisture Content

Desired Moisture

Temperature

Airflow

Pressure

Chemical Properties

Heat Transfer Coefficent

Time

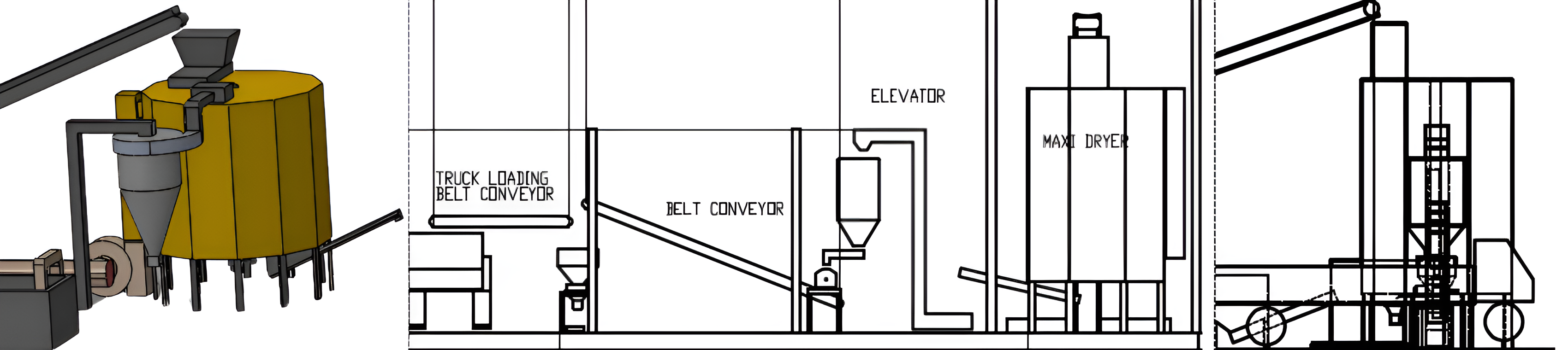

Drying Plant Manufacturing

The design of an ideal drying plant requires a broad vision. It is useful to remember that there is no single solution for every situation. Therefore, before selecting drying equipment, the objectives to be achieved in the drying process must be clearly defined. It is essential to know the physical and chemical properties of the material to be dried and to combine production and process knowledge of dryers operating on different principles. Here are some of the evaluation criteria for drying equipment selection within the scope of process engineering:

Type of Material to be Dried

A granular materials, for example, needs dryers that allow better airflow and freer movement to ensure even drying. Or materials such as filter cakes require dryers that allow mechanical agitation or low pressure to dry without damage. It is therefore important to be able to understand the material-drying process relationship.

- Powder

- Paste

- Pellet

- Granule

- Sludge

- Crystal

- Slurry

- Bead

- Pellet

- Flake

- Filter Cake

- Solid

- Chunk

Drying Equipments

It is also important to have a good understanding of the working principles of drying equipment and to have the ‘know-how’ of which system is more advantageous in which situations. Assessing the situation from a purely academic perspective is in most cases insufficient. Therefore, it is always necessary to consider capacities, possibilities, investment and operating costs.

- Maxi Dryer: Vertically arranged, multi-tray rotary drying system.

- Rotary Dryer: Rotating cylindrical drum to dry materials by tumbling them in hot air or gas.

- Belt Dryer: Conveyor belt to slowly transport materials through a heated chamber.

- Flash Dryer: Rapid drying system that uses a high-speed hot air stream.

- Fluidized Bed Dryer: Drying system that suspends particles and mixes them thoroughly with a hot air.

- Spray Dryer: Drying system that atomizes liquid or slurry into fine droplets.

Chemical Properties

Chemical properties are a critical parameter, especially for drying heat-sensitive or reactive materials. For example, the risk of explosion should be considered when drying a chemical containing organic solvents. For such products, dryers that can operate under vacuum are generally preferred. Because this allows drying at lower temperatures.

Thermal Behavior Characteristics

Some analyses are used to determine the thermal properties of the material. The data obtained as a result of these analyzes can be useful for determining the drying temperature. For example, DSC analysis of a material can show the melting point or decomposition temperatures of the material, allowing a drying process to be planned below these temperatures.

Porosity of the Material

Porous materials help to shorten drying times as they facilitate the entry of air into them. For non-porous structures, dryers with sufficient evaporation from the surface may be preferred.

Structural Degradation

Materials at risk of structural degradation, such as pharmaceutical tablets or biotechnological products, require gentle drying. Pilot testing before system sizing in such materials is particularly important for process success.

As a result, designing an ideal industrial drying system requires the ability to evaluate a number of parameters together. With more than 40 years of experience in thermal process solutions, GENEMA always with you!

Industrial Drying Plant Design

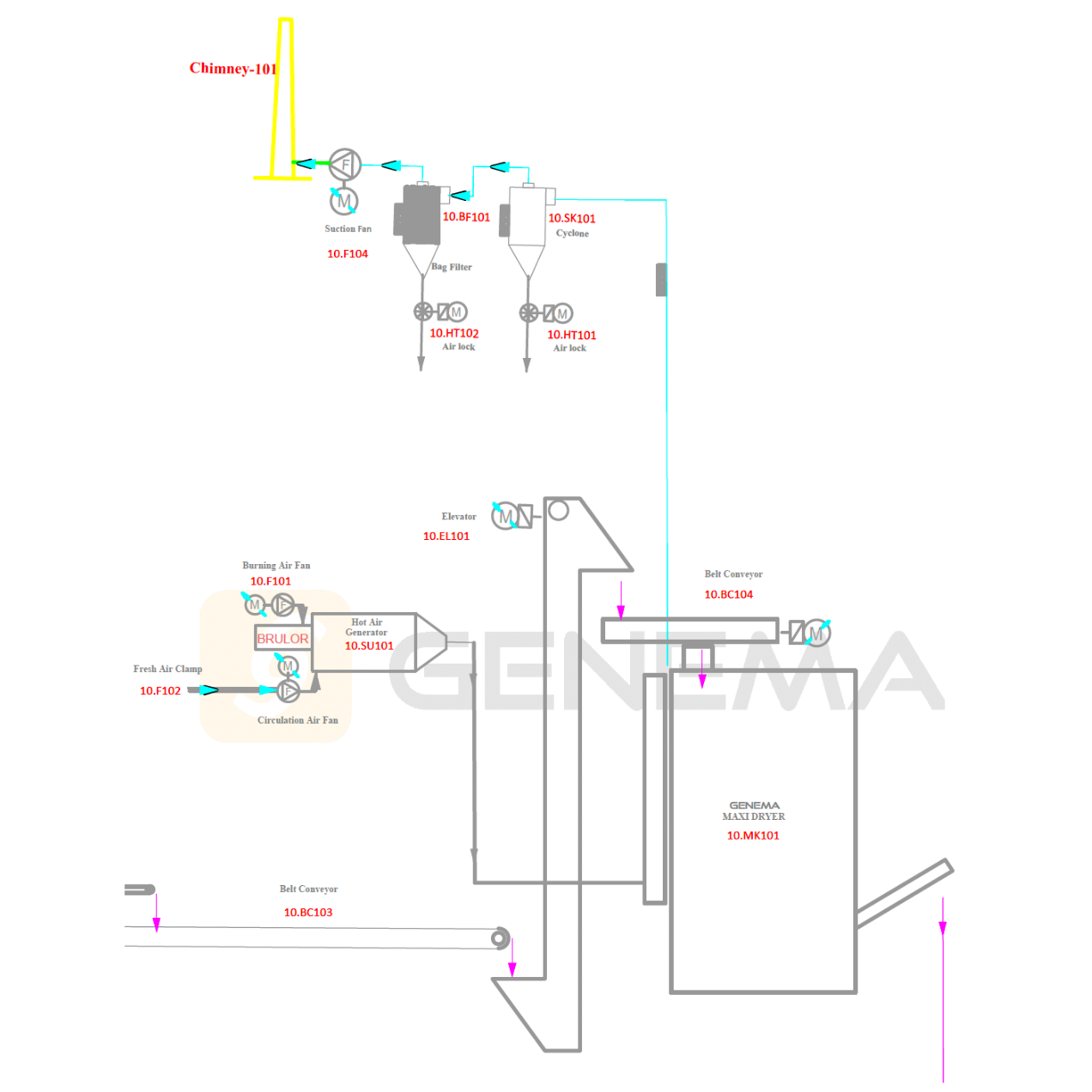

Crushed Material- Biomass Industry

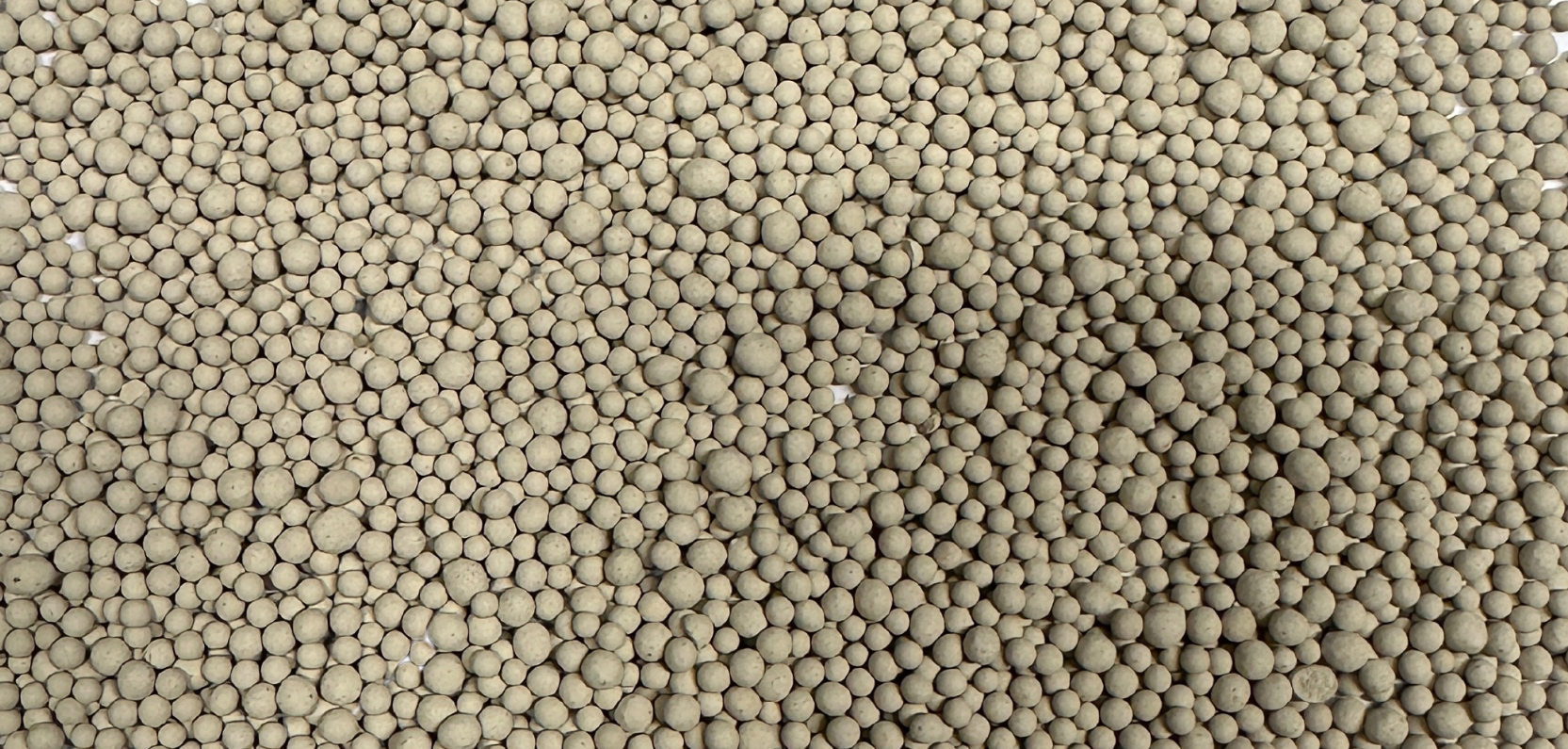

Granular Product- Mining Industry

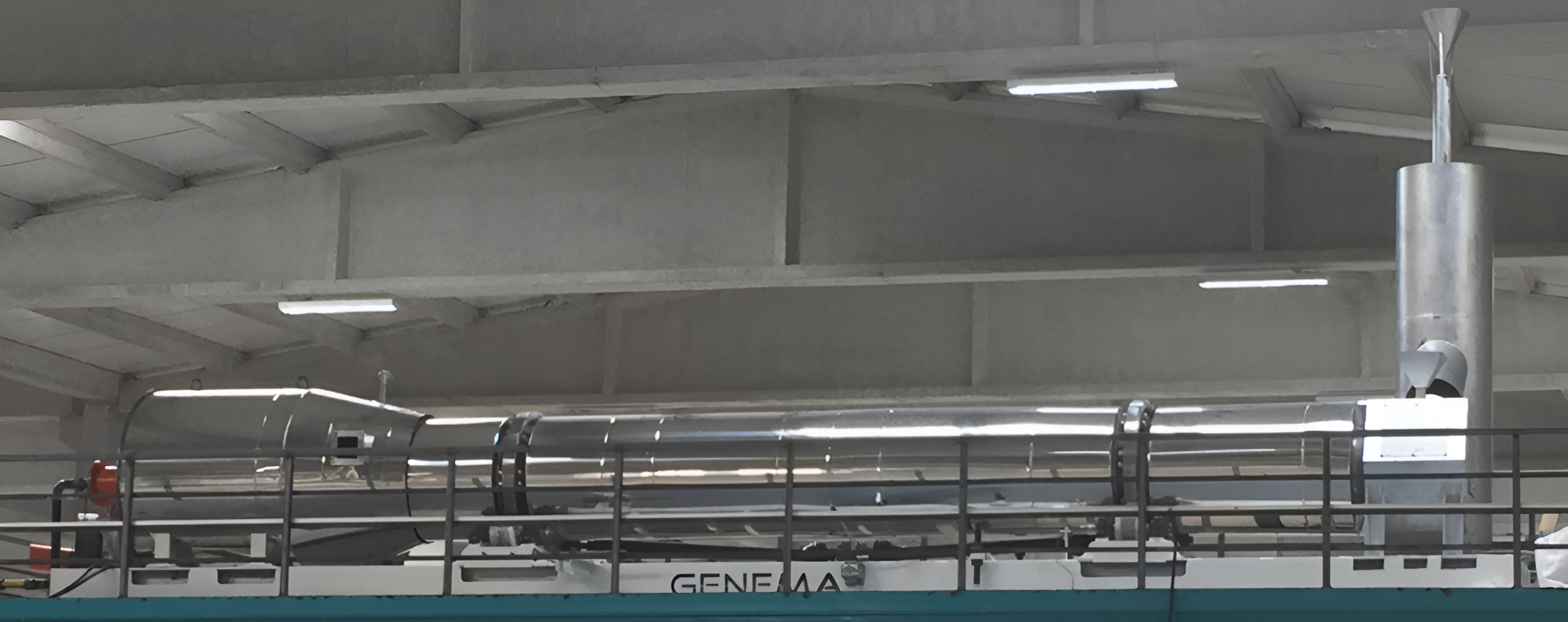

Rotary Dryer for Mineral Drying- GENEMA 2023

Rotary Calcination Furnace for Molecular Sieve Production- GENEMA 2019

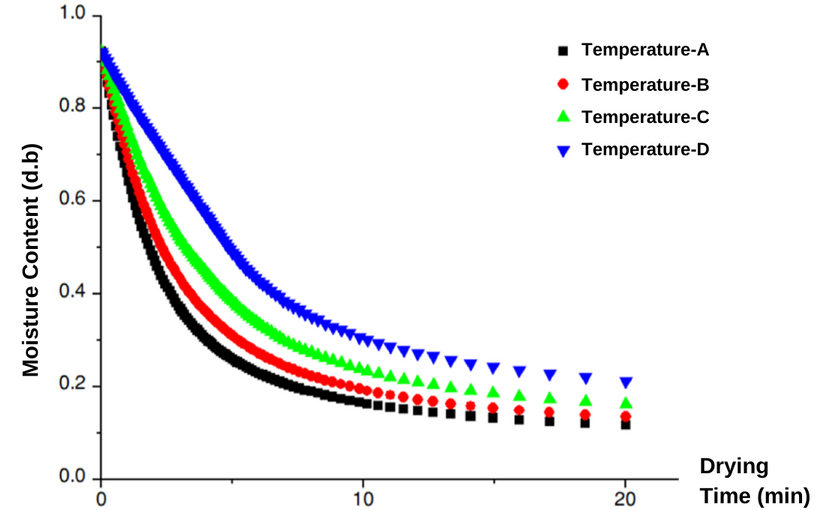

Example Graph for Industrial Biomass Drying Process

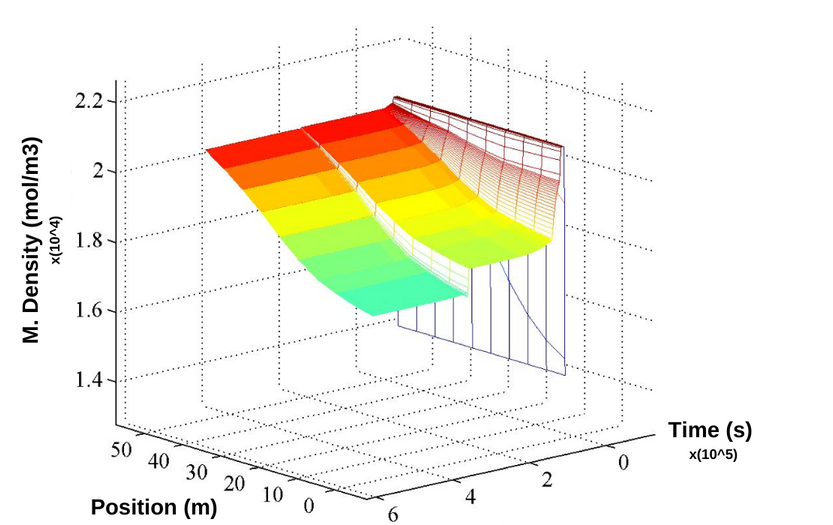

Degradation graph for Calcium Carbonate Calcination