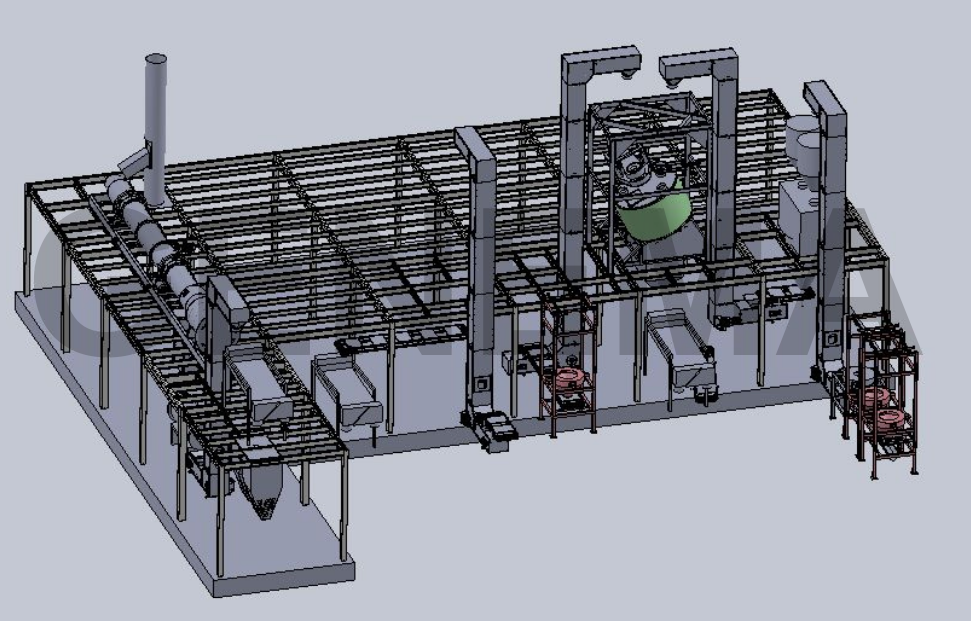

Molecular Sieve Desiccant Production Plant

Molecular sieve desiccants actively remove moisture in insulating glass units. These highly porous, crystalline substances boast tiny pores that selectively sieve out water molecules from air or gas.

The manufacturing process of insulating glass typically involves filling the space between two or more glass panes with dry air or inert gases like argon or krypton. This arrangement significantly reduces heat transfer across the building envelope, enhancing insulation efficiency.

To ensure this space remains dry and devoid of moisture, manufacturers use molecular sieve desiccants. They place these desiccants within the spacer bars that separate the glass panes.

The unique design of these molecular sieves lets them permit entry to water molecules while blocking most other molecules. This characteristic effectively keeps the moisture out, thereby enhancing the longevity and performance of the insulating glass unit.

By continuously removing moisture, molecular sieve desiccants prevent potential condensation problems that can cause fogging or frosting inside the insulating glass unit. However, this not only maintains the glass’s clarity but also ensures the insulation remains effective.

Mastering the Art of Granulation

At GENEMA, we understand that the cornerstone of effective molecular sieve desiccant production lies in the granulation process. It is here that the foundation for superior desiccant performance is laid. Moreover, our technical expertise and comprehensive understanding of granulation techniques enable us to offer top-tier molecular sieve desiccant production plants that yield high-quality desiccants.

Unmatched Granulation Proficiency

Our years of experience in the industry have equipped us with an in-depth understanding of the granulation process and its nuances. GENEMA’s expert team manages factors such as particle size, moisture content, and binder ratio to ensure optimal granulation yields.

You can click the link to see the general granule structure: Granules

3A Molecular Sieve

The 3A molecular sieve stands out as a popular choice for this application. The ‘3A’ denotes a pore size of 3 angstroms, an optimal size for trapping water molecules. Also, this usage contributes to creating high-performing, long-lasting insulating glass units.

Click to view our granule machines: Turbo Granulator

Consequently, we remain steadfast in our pursuit of innovation and improvement, because at GENEMA, we understand that your success is our success. So why wait? Embark on your journey towards molecular sieve desiccant production with us today.