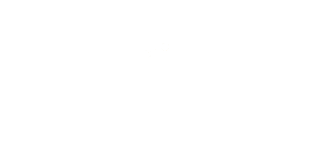

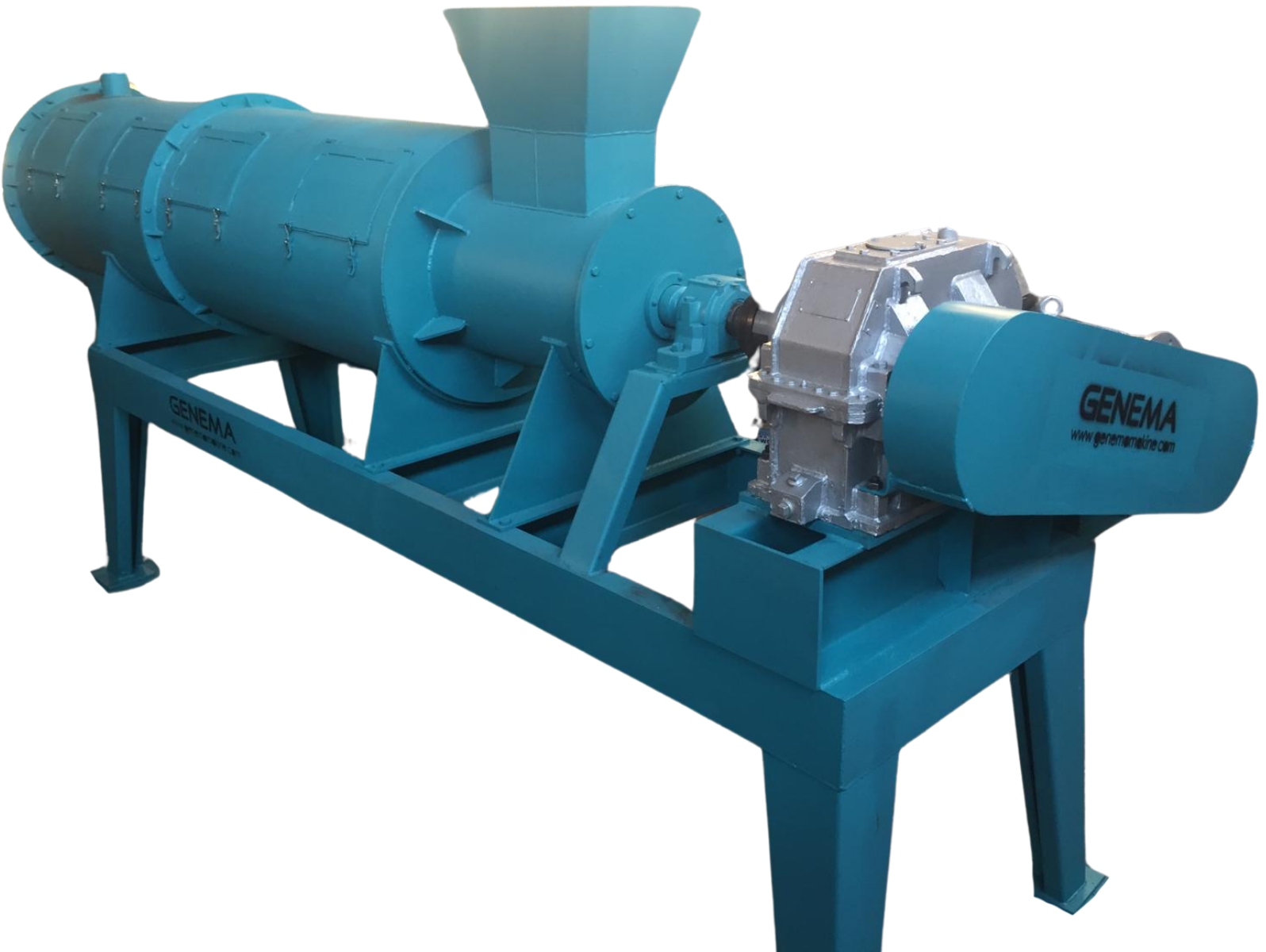

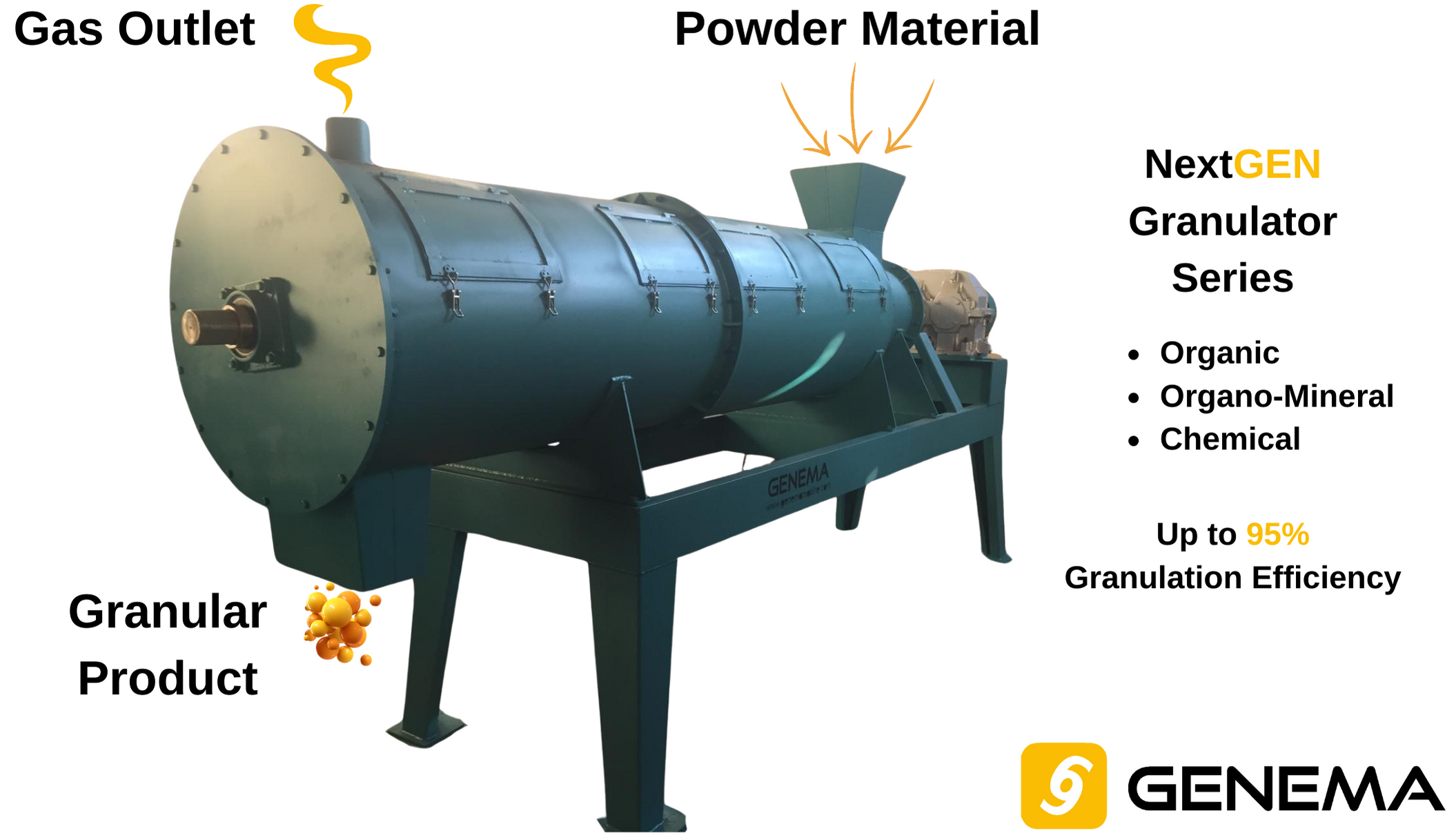

New Type Granulator

Features of the New Type Granulator -NextGEN

- Suitable for continuous process operation.

- The speed of the motor can be easily adjusted according to the process.

- The placement angle of the granulator is adjustable.

- Process control in new type granulator is relatively simple compared to other granulation methods.

- The frictional heat generated during operation allows the material to lose moisture, reducing the costs of drying after granulation.

- Medium-high hardness granules are obtained.

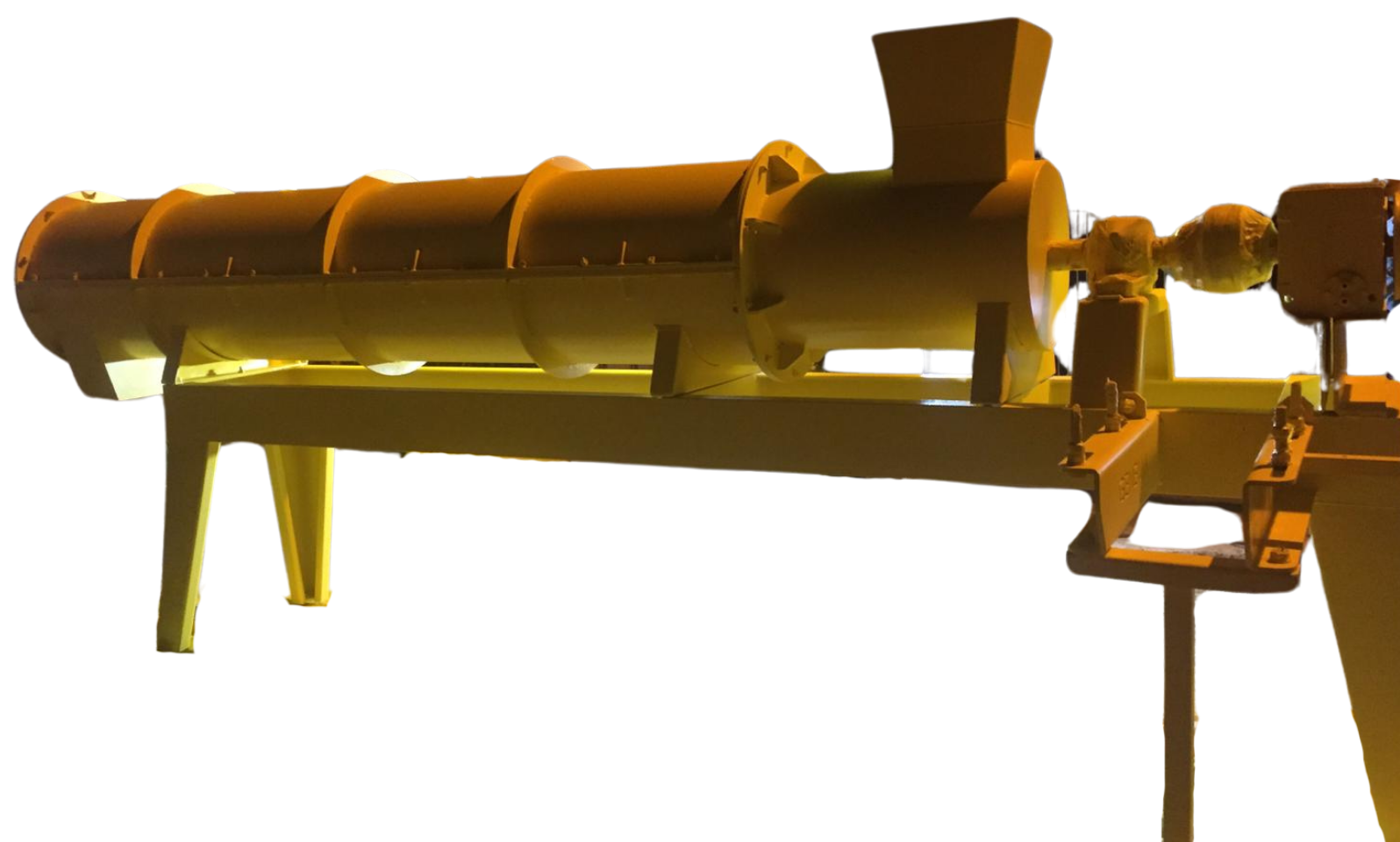

- Easy to clean with openable lids.

- Resistant to abrasion and adhesion with its special inner coating.

- Long service life with easily replaceable tip sets.

New Type Granulator for Fertilizer Granulation

First of all, 2-4 mm granular products are generally preferred in the fertilizer industry. Because in this way, large farmers can easily spread the granular product on the soil by means of mechanical equipment such as ‘drill’ etc.

Secondly, it is a very important criterion that granular fertilizer does not disperse in the sack when filled into sacks. Considering that the sacks can be stacked on top of each other and may undergo a shaky transportation operation, it becomes even more important that the granules have the appropriate strength. So; the granulation system we will prefer in the fertilizer industry must meet these two conditions. In addition, system efficiency is also very critical. Traditionally, rotary drum granulators have taken place in the fertilizer industry. Although this type of systems can produce capacities of 15 tons/hour and above in a single unit, the recycling rates limit the process efficiency and cause extra resource usage. Because in rotary drum granulators, the product is passed through the drum 2-3 times to get its final shape. This causes an unnecessary drum to be kept in the production area and creates disadvantages in terms of electricity and labor.

New type fertilizer granulators provide unique advantages in this respect. Because in a single operation, it both achieves 2-4 mm high-strength granule with up to 95% efficiency and creates a small amount of micro-granules (no dust). Microgranules can also be packaged and converted into a commercial value.

In a single operation, new type granulator can achieves 2-4 mm high-strength granule with up to 95% efficiency and creates a small amount of micro-granules (no dust).

As a result, the main granulated 2-4 mm fertilizer is created simply and efficiently.

NextGEN- New Type Granulator Auxiliary Units

Although it is possible to feed the granulation system manually, it is recommended to use the GRF-Regular feeding unit to achieve the desired high production capacity.

GRF Unit includes:

- Feed Bunker

- Conveyor

- Elevator

- Binder Preparation Unit (If need)

- Continuous Mixer

- Process Control/Automation System

New Type Granulator for Chemical Granulation

The new type of granulator is also very effective for granulation of chemical substances. By controlling rotational speeds and process conditions, micro or macro granules can be easily achieved. Although many substances such as chemical salts, food additives, detergent derivatives and NPK components can be granulated with the standard unit, it is recommended to use custom designed GENEMA granulators for chemicals with intense chemical interactions.

New Type Fertilizer Granulator

Mineral/Chemical Fertilizer Granulation Equipment

Granule Making Machine

NextGEN- New Type Organic Fertilizer Granulator

| NextGEN40 | NextGEN80 | NextGEN120 | NextGEN150 | |

|---|---|---|---|---|

| Capacity | 0.75-1.5 ton/h | 1.5-3 ton/h | 4-6 ton/h | 8-10 ton/h |

| Motor Power | 37 kW | 55 kW | 90 kW | 110 kW |

| Dimension-LxWxH (mm) | 4200*1450*1050 | 4250*1850*1300 | 4900*2550*1800 | 5500*2800*2000 |

| Datasheet | NextGEN40-Granulator | NextGEN80-Granulator | NextGEN120-Granulator | NextGEN150-Granulator |