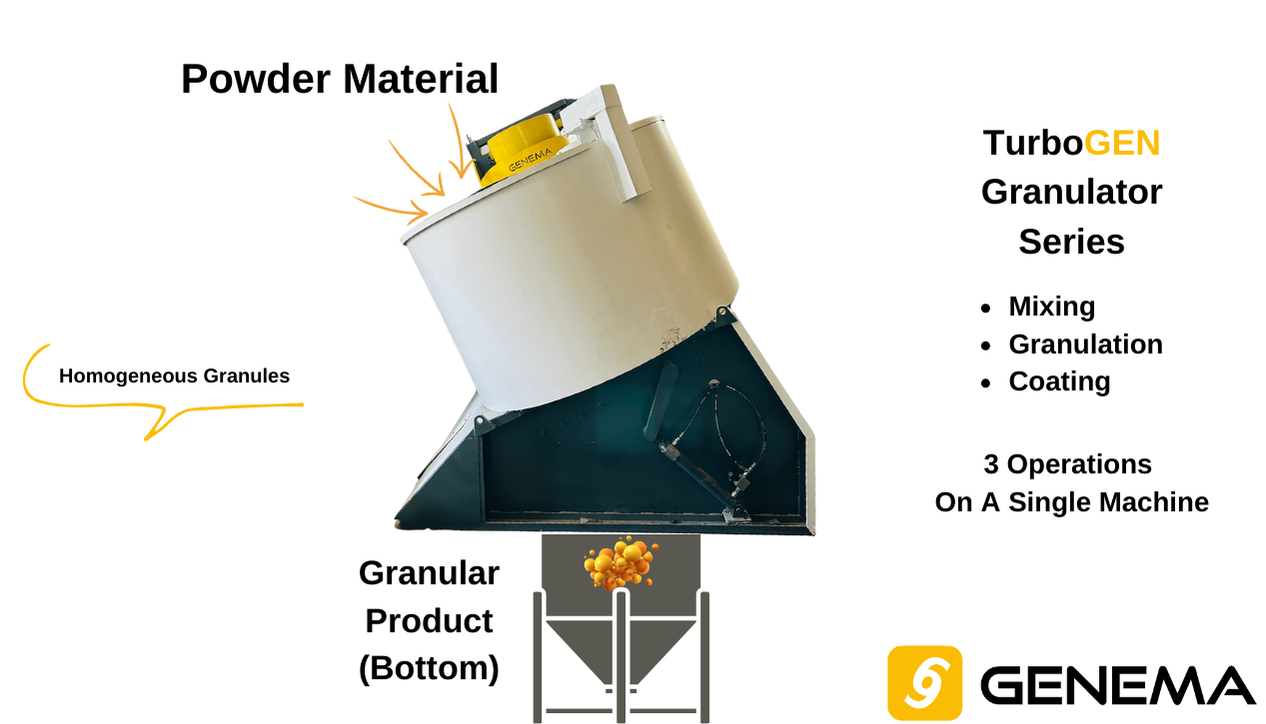

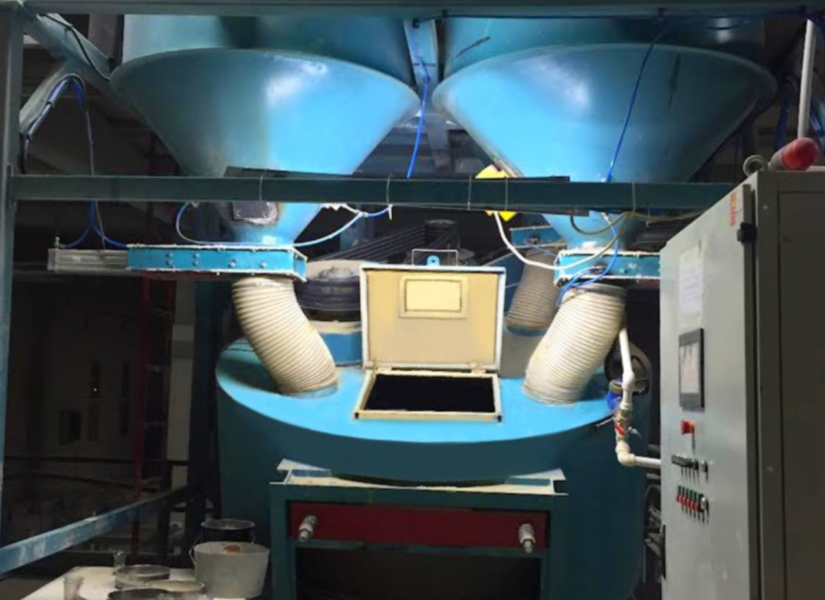

Inclined Intensive Mixer

Advantages of the Inclined Intensive Mixer -TurboGEN

- Capable of mixing dry powders, pastes, slurries, and liquids.

- The special inclined design provides homogeneous mixing.

- Intensive mixer technology achieves the desired product in less time.

- Process optimization can be achieved by adjusting pan and rotor speeds.

- The pan can be operated in both directions, depending on the process.

- The granulation process can be performed in the same machine by changing the mixing tip.

- It provides ease of operation in industrial plants with its under-mixer discharge system.

Intensive Mixer -TurboGEN vs. Horizontal Mixer

While horizontal agitators generally promote lateral and axial movement, inclined intensive mixers allow for three-dimensional movement of materials. This provides superior mixing efficiency by design.

Secondarily, the inclined intensive mixer can apply higher shear forces to the materials, resulting in better dispersion of the ingredients. This is particularly beneficial in formulations that require high precision.

Lastly, horizontal mixers have specific load levels to work well. The inclined intensive mixer, on the other hand, can operate at different load levels without significant losses in efficiency.

TurboGEN Mixer vs. Vertical Mixer

Inclined mixers, due to their design, generally take up less space compared to vertical mixers, which can be particularly tall and require more vertical space.

Additionally, the inclined configuration assists the mixing process by utilizing gravity and improves the mixing action compared to a vertical mixer where materials move mostly vertically.

Lastly, inclined intensive mixer TurboGEN are more energy efficient than vertical mixers because the gravity effect reduces the energy required to move the materials.

TurboGEN vs. Drum Mixer

Inclined intensive mixers generally achieve faster mixing times than drum mixers due to more aggressive and controlled mixing action.

Due to their intense mixing capabilities, inclined mixers can produce more consistent results, which is especially important in industries such as pharmaceuticals and chemicals. Drum mixers can struggle with uniformity, especially with large or heterogeneous batches.

The design of inclined intensive mixers typically allows for easier and more complete discharge of materials and simpler cleaning processes, while drum mixers can have dead zones and can be difficult to clean thoroughly.

Granulation in TurboGEN

TurboGEN inclined intensive mixer/granulators can handle a wide variety of powdered raw materials. This machine facilitates the granulation of different materials used across various industries. Here are some powder raw materials that can be used in an TurboGEN granulator:

- Ceramic Powders: Porcelain, ceramics and refractory materials

- Metal Powders: Aluminum, iron, copper and their alloys

- Chemical Substances: Chemical fertilizers, detergents, chemical reactants

- Pharmaceutical Materials: Active ingredients, excipients

- Food Products: Tea, coffee, spices

- Construction: Cement, gypsum

- Biomass: Compost, biochar

- Special products: Lithium-ion compounds, graphite compounds

Inclined Intensive Mixer

Powder Granulator

Intensive Granulator