Compost Machines

Container Type Composter

Pool Type Composter

Compost Turner

Would you like us to compost your organic waste?

Composting Services

Municipalities

Agricultural Enterprises

Factories

Hotels

Biogas Plants

Chain Markets

Urban Waste Plants

Slaughterhouse

Composting

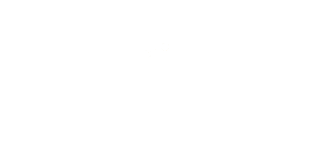

Typical Flowchart

Composting Method

C:N Ratio

Material Particle Size

Moisture Content

Aeration

Oxygen Level

Temperature

Porosity

Mixing

pH

COMPOST MACHINE

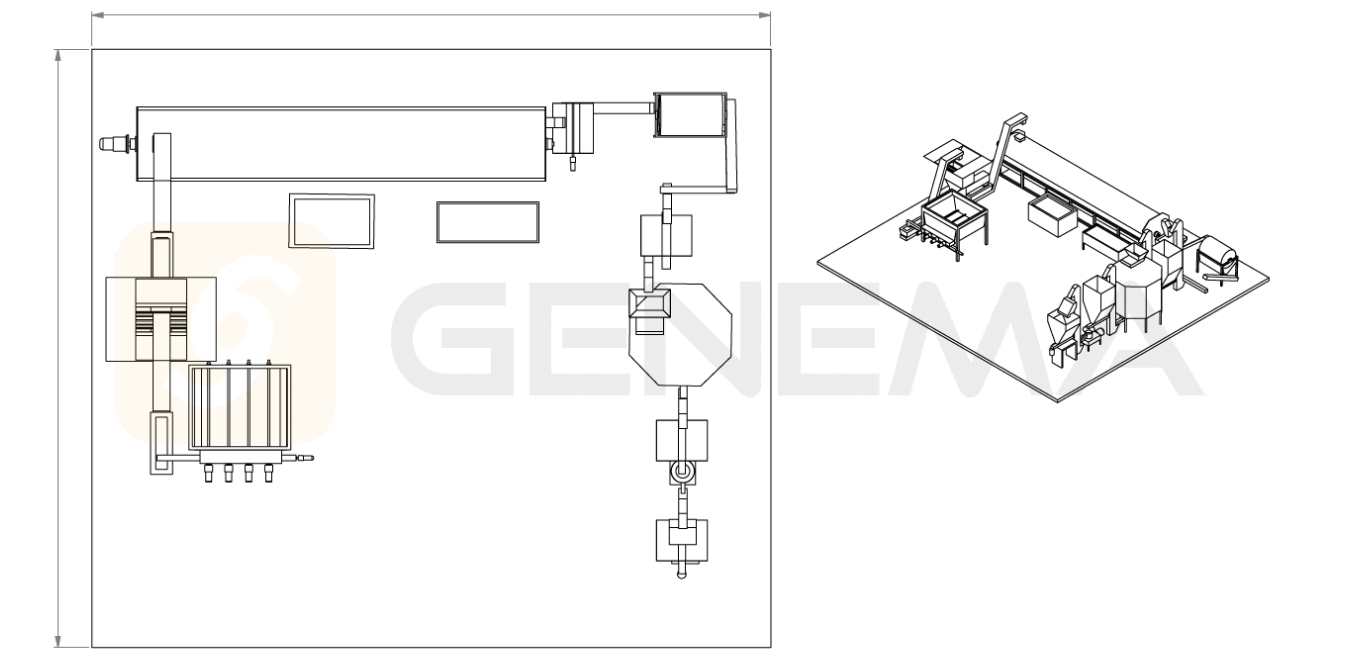

The recovery of organic waste, such as food waste or animal manure, is undoubtedly of great importance for sustainability and environmental protection. When designing composters, GENEMA analyzes in detail all the impacts during the operation of the process. In particular, the environmental impact assessment of closed system composting applications is meticulously performed.

Small Scale Composters

Companies often buy small-scale composters to recycle their everyday waste. This could be food waste from their cafeterias or branches from their gardens. From this point of view, we can say that the volumes of small-scale composters are usually 50-500 liters. The purpose of such investments is sometimes to implement zero waste guidelines and sometimes to create a collective consciousness. Nowadays, people care that the companies they work for or the companies they shop with have a high environmental awareness. In fact, this is what should have been the case throughout history, but whether you call it coercion in line with sustainable development goals or certification to avoid taxing waste, the stones are just falling into place and it is imperative to build our future on an environmentalist ground.

Medium Scale Compost Machine

Investments in this type of closed system composters are sometimes focused on commercial and sometimes on social impact. A medium-sized system can have a volume of 1000-7000 liters. Therefore, the companies that produce the amount of waste required to feed such a system are usually fruit and vegetable pulpers or market vendors. Because even if there are exceptions, it is difficult to find a business that produces food waste on this scale. When we consider composting animal manure as a different issue, these figures remain very small. The daily manure of 10-15 cattle can easily fill a medium-sized composting machine. Therefore, there is some instability in medium-scale machine installations. Because of all these, municipalities mostly prefer this type of units.

Large Scale Compost Machine

There are many small-scale composting companies but few large-scale composting companies. The reason for this is the balances mentioned at the beginning of this article. Energy efficiencies and process economics are very important in large-scale composting applications. Ultimately, companies that establish large-scale compost facilities have to make a profit in order to sustain their businesses. The market must accept the compost product they produce. Regular physical and chemical analysis is essential to ensure this. You cannot promote every blackened organic waste as compost fertilizer. Your process and mechanical line must work without interruption. For all these reasons, industrial composting requires a rigorous engineering study and mechanical manufacturing experience in accordance with international standards.

Composting Scale

Although the science of composting is quite old and well-known, the importance of the composting process has increased with the increase in the importance of the composting process today, and the issues to be considered when choosing a composting system have also increased. One of the first considerations when choosing a composting system is now “scale”. Because, for example, the composting of daily food waste generated in hotels and restaurants and the composting of organic waste of an entire city are different in terms of the complexity of the project, even though the biological principles are the same. A balance must be struck in terms of project feasibility, investment and operating capital, and environmental impacts. Only in this way will the momentum of composting technologies in the world increase.

For more information: Key parameters of composting systems