Industrial Autoclave

Industrial Autoclave Features

- Suitable for high pressure and temperature operation.

- Optimum heat dissipation.

- Modular and scalable.

- Advanced HMI interface.

- Manufactured in accordance with safety regulations.

Dewaxing Autoclave

A dewaxing autoclave is a machine usually used in foundries.

This machine is used in the mold making process in investment casting.

The main function of a dewaxing autoclave is to melt out the wax pattern contained in a ceramic shell.

The process takes place as follows:

- Wax Model and Ceramic Shell Preparation: First, a wax model of the part to be cast is made.

This wax model is hardened by covering it with a ceramic shell material.

Thus, the wax model remains inside the ceramic shell. - Melting the Wax: The prepared ceramic shell is placed in a dewaxing autoclave.

The autoclave melts the wax inside the shell using high pressure steam.

As the wax melts, it flows out of the ceramic shell and only the ceramic shell remains. - Preparation for Casting: After the wax is removed, the ceramic shell is ready for casting.

The desired metal is poured into this empty shell and after the metal solidifies, the ceramic shell is broken off.

Benefits of a Dewaxing Autoclave:

- Precision: Dewaxing autoclaves provide high accuracy in the production of complex shapes and precise details.

- Efficiency: This method allows the wax to be removed quickly and efficiently, thus speeding up the casting process.

- Quality: Prevents damage to the ceramic shell during the dewaxing process and helps to ensure high quality castings.

As a result, the dewaxing autoclave is a critical part of the investment casting process in foundries and plays an important role in the production of precise, detailed castings.

Industries Using Investment Casting Autoclave for Precision Manufacturing

The investment casting autoclave is a crucial piece of equipment for industries that require high-precision metal parts with complex geometries. From aerospace to medical devices, these autoclaves ensure efficient and accurate wax removal in the investment casting process, enabling the production of intricate and high-quality metal components. Below are the key industries that benefit from using investment casting autoclaves:

Key Industries Using Investment Casting Autoclaves

A- Aerospace and Defense

The aerospace and defense sectors require lightweight, durable components for engines, turbines, and structural parts. With an investment casting autoclave, manufacturers in these industries can produce complex metal parts with precision, meeting the strict quality standards of aerospace and military applications.

B- Automotive Industry

In the automotive industry, investment casting autoclaves are used to create high-performance parts such as engine components, gears, and suspension systems. The ability to cast intricate shapes with exceptional accuracy helps automotive companies produce durable and efficient parts that improve vehicle performance.

C- Medical Device Manufacturing

Medical devices such as implants, surgical instruments, and prosthetics require extreme precision and biocompatibility. The investment casting autoclave plays a key role in producing these critical components, ensuring that complex shapes are achieved with accuracy while maintaining the quality and integrity of the final product.

Other Industries Using Investment Casting Autoclaves

A- Power Generation

Companies in the energy sector rely on investment casting autoclaves to produce components for turbines, pumps, and valves. These parts are essential for the efficient functioning of power plants and other energy-related systems, where reliability and durability are critical.

B- Industrial Machinery

The industrial machinery sector uses investment casting autoclaves to produce intricate parts for pumps, compressors, and heavy machinery. By enabling the precise creation of complex metal components, autoclaves ensure that machinery parts are durable, reliable, and perform at optimal levels.

C- Marine Industry

Marine manufacturers use investment casting autoclaves to create precision components like propellers, valves, and ship engine parts. The autoclave ensures the production of corrosion-resistant metal components that can withstand harsh marine environments, improving the durability and longevity of the equipment.

D- Jewelry Manufacturing

For luxury jewelry brands, investment casting autoclaves enable the creation of intricate designs with fine details. The ability to cast delicate shapes with precision allows for the production of high-quality, intricate jewelry pieces that meet the expectations of fine jewelry markets.

E- Firearms and Defense Equipment

Manufacturers of firearms and defense equipment utilize investment casting autoclaves to produce durable, high-precision metal components. The autoclave ensures consistent quality and strength in metal parts, which are essential for the performance and safety of defense equipment.

In conclusion; Industrial autoclave is a machine that appeals to many sectors. We will be pleased to serve you with our production experience in this field.

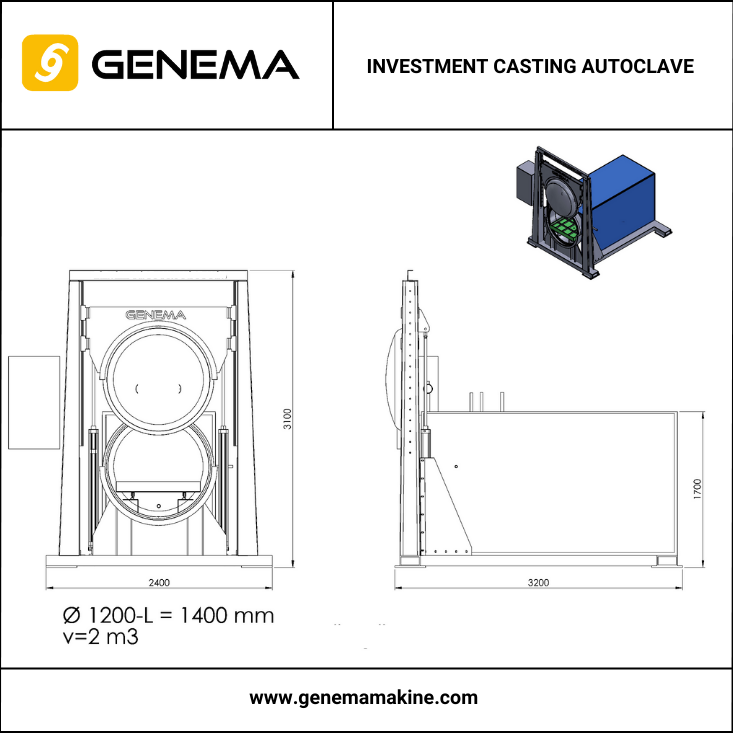

Investment Casting Autoclave