Granulation Plant

Granulation plant installation is a priority for the following businesses:

- Mining companies

- Fertilizer companies

- Waste recycling companies

- Chemical producers

- Food additive producers

- Cosmetics industry

- Pharmaceutical producers

Before the granulation plant is established, its pre-feasibility should be done. It is beneficial to include the following sections in this feasibility:

- Market research

- Location of the project

- Trial production results

- Technology

- Flow chart

- Industrial sizing

- Technical specifications

- Financial analysis

- Sustainability

Undoubtedly, trial production of granules gains vital importance when you are sure of the market and can easily organize production possibilities. The granulation technology you choose will often play the most important role in your business success. Pan type, rotary drum type conventional granulation units have increased process efficiency concerns in recent years. Conventional granulators often put the investor in a dead end when the products are also taken into account, the excess of recycle needs and operational energy costs. The way out of this deadlock is possible by following the process below:

- Determination of process requirements

- Establishment of operational costs

- Optimization of binder type and quantity

- Understanding energy needs

- Determination of granulation process time and yield

The establishment of a granulation plant is meaningless without the use of experience-based granulation technique and modern granulators to operate this process. Therefore, satisfactory results; It requires knowledge, experience and the ability to apply on existing modern machines. In addition, the selection of equipment for the pre- and post-granulation processes is also essential. These processes can be as follows:

Additional processes in granulation plant

- Grinding

- Mixing

- Drying

- Cooling

- Sieving

- Packaging

Choosing drying equipment based on post-granulation optimization values prevents unnecessary machinery investments. In addition, if the raw material is suitable instead of choosing a rotary drum dryer for drying, choosing a Genema Maxi Dryer will significantly reduce the energy costs in the process.

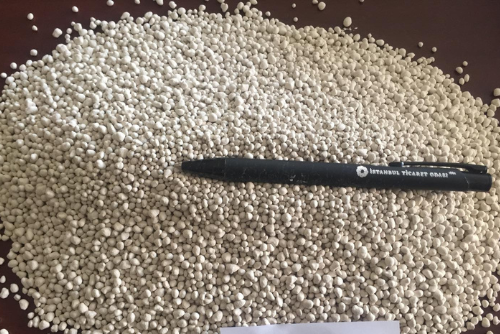

Before supplying the granular product industrially, it is quite suitable for human nature to take it by hand and see it with the eye. It is clear that only the companies that provide this opportunity will be able to hold on in the sector and develop their know-how.

Genema manufactures state-of-the-art granulation systems and also carries out sample production in its own pilot plants. It ensures the efficiency of the process and product quality by using high-quality sensors and software to optimize process parameters. Some granule samples produced by Genema in its pilot or industrial facilities are listed below.

Samples after granulation

You can check granulators: Organic Fertilizer Granulator Machine, Turbo Granulator

You can read the articles about laboratory scale granulation tests: Lab Scale Granulation