What is industrial dryer?

They are systems designed to reduce large amounts of material to low humidity. Fluid bed dryers, rotary dryers, spray dryers and the maxi dryer which is the main subject of our article are among these systems.

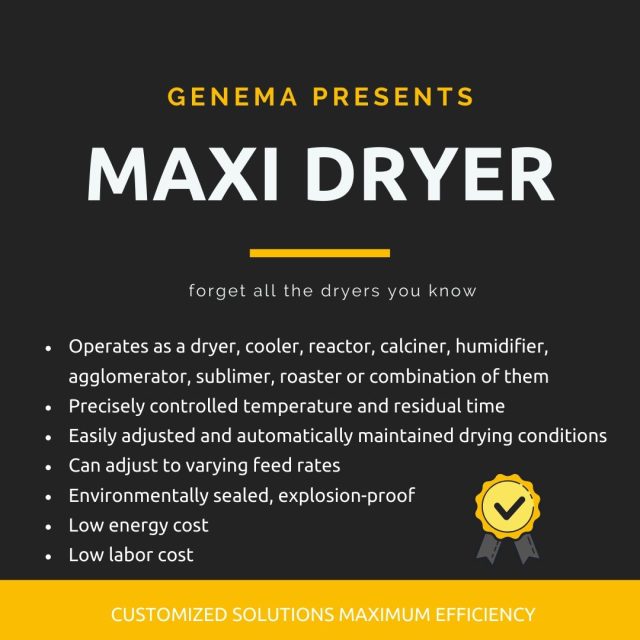

Why Maxi Dryer is different?

It works according to the principle of circulating heated air or gas with internal fans methodologically. The material changes layers in each cycle. In this way, you get the effect of very long drying conveyors. In addition, energy saving is excellent. It is a vertical system. It requires low space and low labor.

What parameters are important for dryer selection?

The best design is customized desing because:

Product size may range from microns to centimeters.

Porosity may range from 0%-99.9%

Drying times range 0.50 s to 3 months.

Capacities may range from 0.20 kg/h to 50 ton/h

Drying temperature and product speed are also very important parameters and variable for different applications.

Operation pressure may range from milibar to 20 atm.

Heat transfer type can be convection, conduction, radiation or electromagnetic fields.

What materials can Maxi Dryer dry?

There is no theoretical limit. The method is suitable for drying many raw materials from different industries. For example; manures, minerals, antioxidants, catalysts, herbicides, prills etc.

Are we talking about a standard size dryer?

It can be fully scaled according to your capacity and expectations. Let’s work together and produce the most suitable design for you!

What else makes it perfect?

This is not ordinary dryer! It can operated as also cooler, reactor, calciner, humidifier, agglomerator, sublimer, roaster or combination of them. Some advantages:

Precisely controlled temperature and residual time.

Easily adjusted and automatically maintained drying conditions.

Can adjust to varying feed rates.

Environmentally sealed, explosion proof

Low energy cost

Low labor cost

Much more than this – Maxi Dryer